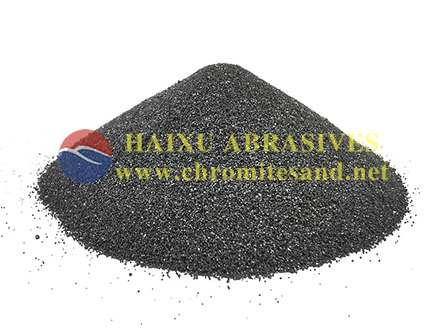

Molding sand Chromite sand AFS40-50 AFS40/50

Molding sand Chromite sand AFS40-50 AFS40/50 is a black casting sand with a semi metallic luster. It comes from chromite ore in nature. Chromite sand has a Mohs hardness of 5.5-6.5 and a specific gravity of 4.3-4.8g/cm3. Natural chromite ore is composed of two parts: spinel and gangue, which are usually associated. Spinel is Mg • FeO Al Cr2O3, gangue is serpentinite H4 Fe • Mg3 Si2O9 (hydrated silicon magnesium), and there are also small amounts of magnesium olivine, quartz, green pyroxene and other forms in chromite. The quartz (SiO2) in it is harmful to the chromite sand used in casting and needs to be removed through processing methods.

Molding sand Chromite sand AFS40-50 AFS40/50 Characteristics:

(1) Chromite sand for steel casting has excellent quenching properties, which do not reduce hot cracking but can affect temperature gradients and promote directional solidification without the need for cold iron. This characteristic is important for large thick walled steel castings. Chromite sand can promote sequential solidification and reduce porosity defects.

(2) Chromite ore sand is inert and therefore does not react with other metal oxides. It is not wetted by manganese steel water. Manganese steel castings can successfully use chromium iron ore sand. If the mold is coated normally and the silicon oxide content is low, there is no iron olivine reaction.

(3) The thermal expansion of chromite sand is small. Linear expansion is a factor that may cause sand inclusion in castings. Therefore, it may be used to mix wet sand molds for large castings.

(4) Chromite sand is sintered through fine-grained sintering, accompanied by quenching and high residual heat strength, eliminating metal penetration and reducing the risk of chemical sand sticking.

(5) Chrome ore sand has strong compatibility and can be used together with various binders, while also belonging to a certain particle size range. Chromite sand can also be mixed with silica sand for use.

(6) The silicon content of chromite sand is low, and cleaning the casting sand can reduce the intake of silicon dust, which will not have a health impact on the human body.

Technical Index of Chromite sand AFS40-50:

1.Chemicals

| Cr2O3 | ≥ 46% |

| SiO2 | ≤ 1.0% |

| FeO | ≤ 26.5% |

| Cr:Fe | ≥1.5:1 |

| MgO | ≤ 10% |

| CaO | ≤ 0.3% |

| Al2O3 | ≤ 15.5% |

| P | ≤30 ppm |

| S | ≤30 ppm |

| Cr/Fe | ≥ 1.55:1 |

2. Physical index:

| Mohs Hardness | 5.5-6 |

| Melting Point | 2180 ℃ |

| Sintering Point | >1800℃ |

| Specific Gravity | 4.0-4.8 g/cm3 |

| Bulk Density (LPD) | 2.5-3 g/cm3 |

| Color | Black |

| PH Value | 7-9 |

| Thermal conductivity | 0.63 W/M·K |

| Thermal Expansion Rate(1000℃) | 0.6% |

| Acid Demand Value (ADV) | ≤ 5ML |

| Turbidity(JTU) | ≤ 110 |

| Soil content | ≤ 0.1% |

| Moisture | ≤ 0.1% |

3. Particle distribution of Chromite sand AFS40-50:

| +30mesh(600um) | 1.60 |

| +40mesh(425um) | 22.00 |

| +50mesh(300um) | 34.50 |

| +70mesh(212um) | 32.90 |

| +100mesh(150um) | 9.00 |

| Grain Fineness(GFN) | AFS 43.47 |

Molding sand Chromite sand AFS40-50 AFS40/50 Applications:

- Large scale thick walled casting: Chromite sand combined with sand casting, furan resin self hardening sand, water glass self hardening sand and other processes are used for large volume and weight cast iron and steel castings. It can cool the castings in a predetermined order, which is conducive to improving the internal tightness of the castings and enhancing their strength. In addition, for the process of using silica sand, chromite ore sand can be used as surface sand instead of silica sand in key areas where porosity and veins are prone to occur, which can effectively prevent casting defects such as cracks and porosity.

- Lost foam casting. In lost foam casting, using chromite sand can prevent defects such as sand inclusion and sticking caused by quartz sand casting. Used for manufacturing castings such as valves and impellers made of high chromium cast steel and high manganese steel materials.

- Shell casting: Chromite sand can be used as a core sand material for complex components in shell casting, making sand cores. Used for producing high-precision, smooth surface 304316 stainless steel castings and carbon steel precision castings. It can effectively prevent the problem of sand sticking in the inner cavity of castings.

- Sand casting: Chromite sand can also be used for sand casting, such as sand casting, water glass self hardening sand casting, etc., to produce various large, medium, and small parts, such as pump bodies, pipelines, valves, etc.

Production of Molding sand Chromite sand AFS40-50 AFS40/50:

Package of Molding sand Chromite sand AFS40-50 AFS40/50:

Latest News:

Chromite sand AFS 40-50 properties and technical Index